Hidden doors (invisible doors)

Hidden doors with an ABS surface are modern constructions that, thanks to their unique installation and design, look like part of the wall, creating the effect of a seamless interior. They feature a concealed aluminum frame flush with the wall, no visible casings, and the use of special concealed hinges.

Door Leaf Design

The door leaf of a hidden door can be finished with the same materials as the...

Hidden doors (invisible doors)

Door Leaf Design

The door leaf of a hidden door can be finished with the same materials as the walls — wallpaper, paint, decorative plaster, veneer, 3D panels, mirrors, or imitations of wood or stone. This allows for visual continuity of the space and emphasizes a minimalist interior style.

Construction and Materials

The frame is made of anodized aluminum, which ensures durability and resistance to moisture, corrosion, and temperature fluctuations. The door leaf is made of plywood and kiln-dried pine timber, filled with honeycomb cardboard for sound insulation. The thickness of the HDF panels is 6 mm (instead of the standard 3 mm).

Hinges

Italian AGB Eclipse 3.0 concealed hinges with three-dimensional (3D) adjustment are used, allowing precise alignment of the door leaf without removing it. The hinges provide smooth, quiet operation and are designed for loads up to 60 kg.

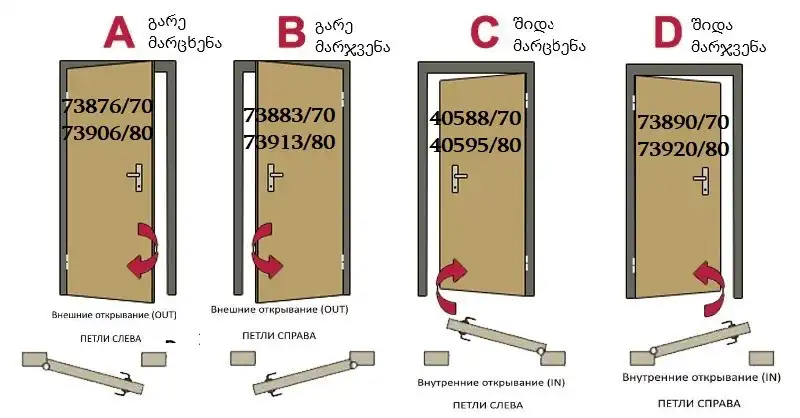

Types of Hidden Doors

- With or without edge banding

- Without edge banding — complete blending with the wall, creating an “invisible” effect, but requires especially careful finishing of the edges.

- With edge banding — a protective edge along the sides, increasing wear resistance and simplifying painting.

Frame Differences

The frame of a hidden door is built into the wall and plastered, creating a unified surface. Unlike standard doors, it doesn’t require casings, and the hinges are completely hidden. The aluminum profile ensures geometric stability and easy installation.

Finishing and Masking / Hidden Doors with ABS Surface

Painting

All doors are supplied primed. For painting, it is recommended to use acrylic or polyurethane paint in two thin layers. To achieve the invisible effect, choose a paint color matching the wall.

Wallpapering

The door leaf can be covered with the same wallpaper as the walls. It is important to match the pattern and carefully trim the edges so that the door fully blends with the surface.

Plastering of Hidden Doors

After installing the aluminum frame, the gaps between the frame and the wall are plastered to create a flat surface. High-quality plastering makes the door visually invisible — contours are visible only when opened.

Door Storage

Doors should be stored in a dry, closed room without temperature or humidity fluctuations, in a vertical position on a flat surface, in factory packaging until installation. Aluminum parts must not be placed on concrete or damp floors. Before installation, the product should be acclimatized indoors for 24–48 hours.

Locks and Fittings

Magnetic or mechanical latch locks with a minimalist design are suitable for hidden doors. Magnetic locks provide silent closing, while electromagnetic ones offer a high level of security.

Installation

Installation is carried out before final wall finishing. Main stages: preparing the opening, installing the aluminum frame, foaming and fixing, hanging the door leaf, hinge adjustment, plastering, and finishing.

Non-Standard Sizes

Non-standard size doors are manufactured on an individual order basis. Production time — about 50 days after the project and measurements are approved.

See information about promotions and training videos on Facebook and Youtube

Reviews

There are no reviews yet.